KnowledgeECONOMICS

CONTACT US

Hunan Perfect Industry Co.,Ltd

Contact: Manager Hu, Manager Yi

Hotline:008618507312158

Cell phone:008613974960765

Address:Xiangyin County Industrial Park, Yueyang City, Hunan Province, China

Current location: HOME »Knowledge »vertical turbine pump

Unloading The Vertical Turbine Pump

It is important to exercise extreme care in handling and installing allparts, particularly the shaft and enclosing tube. All items are preci-sion machined for proper alignment and, if dropped, banged, sprungor mistreated in any way, misalignment and malfunction will result.Parts which are too heavy to be lifted from the transporting car ortruck should be skidded slowly and carefully to the ground so as toprevent injury. Never unload by dropping parts directly from the car-rier to the ground and never use shipping crates for skids.

If your vertical turbine pump is a short set turbine, a twenty (20) foot setting or less,you might be able to install it directly from the truck that delivered itto you. lf the truck driver has the time and if he can back his vehicle inclose to the wellhead the parts can be handled directly from the truckbed by the vertical turbine pump rig as the installation progresses.

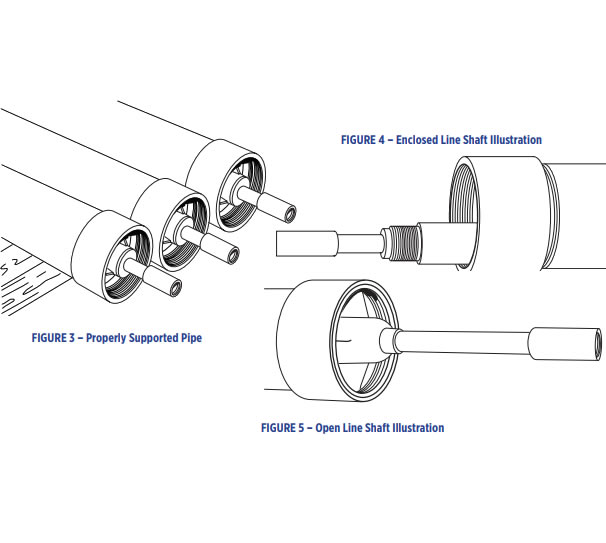

For longer units, layout column pipe and the bowl assembly onsuitable timbers or staging to keep all materlal out of the dirt. seeFIGURE3. Position coupling ends toward the wellhead. lnner columnjoints consisting of shafting and/or tubing with line shaft bearings willhave been pre-assembled for you at the factoryinto proper lengthsto match the column pipe. insert these assemblies into the matchingpipe sections, with the projecting line shaft bearing pointing towardthe well. See FlGURE 4 for enclosed line shaft and FlGURE 5 for openline shaft illustrations.

Tube faces should be inspected to see that they are free from burrs ornicks and, in the process, should be wiped clean. Sections that havebeen assembled at the factory should be checked for tightness by yourinstaller to insure none have loosened during transit. You should alsocheck each joint for straightness as a bent tube cannot be used. Keepends covered until each is ready for installation.

If the line shaft was received in a crate, we suggest you handle itdirectly from the crate. if not, place each length on timbers and cleanwith solvent to remove rust preventive, oll or flushing compound. ineither case, inspect each joint to make sure the faces are undamagedand that the plece is absolutely straight. Each was heat stralghtenedbefore shipment from the factory and if any were bent in transit, theycannot be used. Keep ends covered until ready for installation.

All other parts should be cleaned and laid out on a suitable surface inthe order in which they will be needed. Check all parts against yourpacking list to be sure none are missing. it's much better to find outnow, than during the installation.